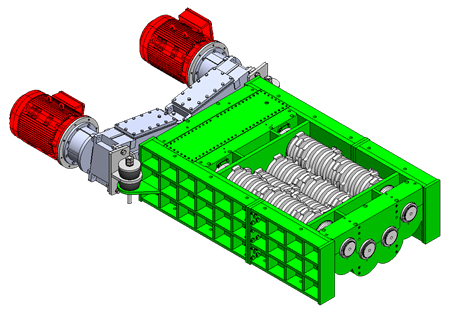

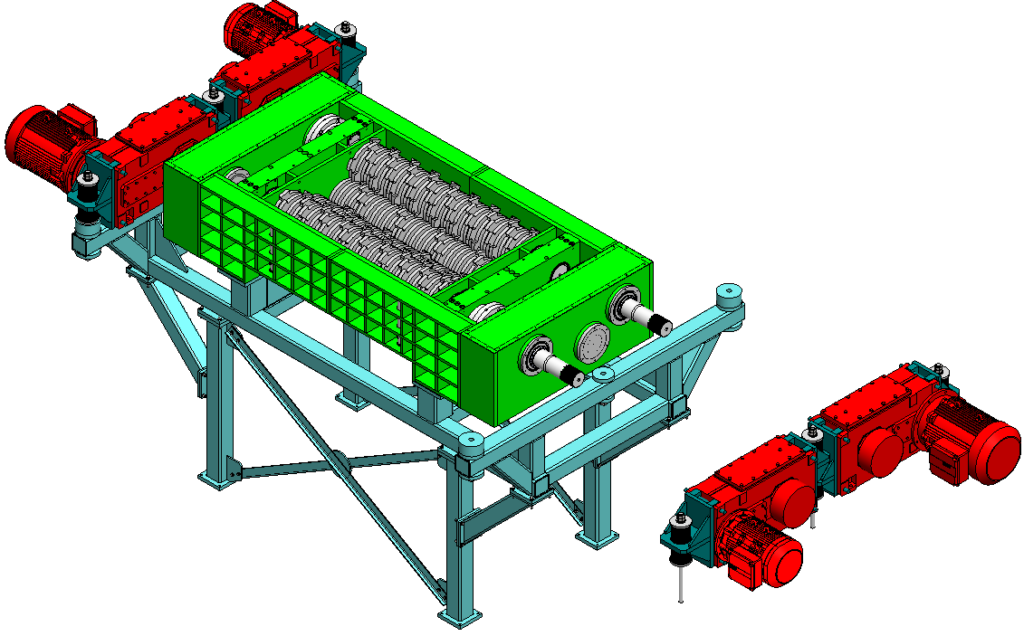

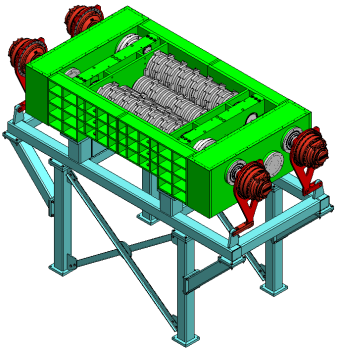

The QUAD series is characterized by a robust design.

Thanks to a specially developed hardfacing process that makes the cutterbar particularly resistant, the QUAD can be operated continuously.

The motorization and the speeds are individually adapted to your requirements. In addition, the QUAD shredder can be equipped with a perforated screen if required. This also achieves levels P3 and P4 of the new DIN 66399 standard in document destruction.

The QUAD series is used for document shredding, tire shredding, refrigerator shredding up to the shredding of complete IBC containers with filling.

In addition, the QUAD II can be equipped with a contaminant flap to provide easy access within an enclosure.

Special feature of the quad:

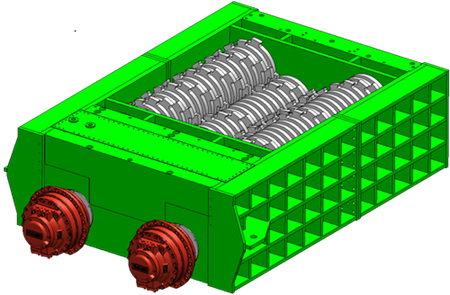

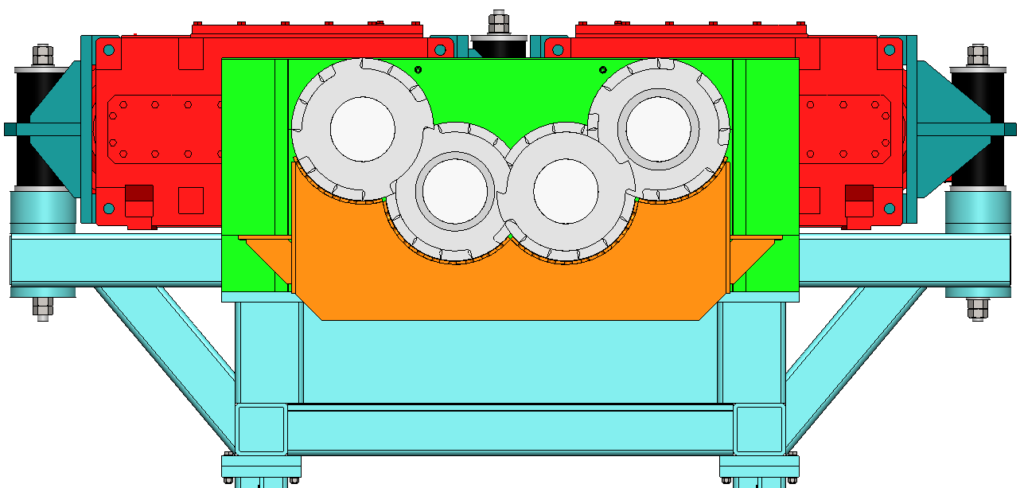

The Quad is characterized by the 4 wave technology. The knife shafts always convey the material to the center of the cutterbar. In addition, it can be equipped with a perforated screen, which then determines the fraction sizes. Fractions that are too large are also fed back to the main cutting shafts via the auxiliary shafts.

Drive power: 2 x 55 kW

Cutting unit opening: 1200 x 1255 mm

Number of slitter shafts: 4

Main shaft speed 5 – 35 /min

Direct drive: yes

Weight: 16800 kg

Driving power: 200

Cutter opening: 1700 x 1680 mm

Number of slitter shafts: 4

Main shaft speed 5 – 35 /min

Direct drive: yes

Hydraulic attribute: optional

Weight 25000 kg

For shredding with high torques and low speeds, the slow-running rotor shears of the Artech RS 85 – RS 140 models are used in a variety of applications as extremely reliable and robust shredders, but without exception as 2-shaft units.

In order to harmonize the cuttings size from this, the material must either be fed to the shredder again by means of subsequent separation technology (return flow) or shredded in further steps (secondary shredder/granulator).

The QUAD II is designed as a 4-shaft machine to achieve the desired cut size in one operation, regardless of the input size.

The upper shafts feed the input material to the lower shafts. The main shredding performance takes place within the lower pair of shafts, material that is not shredded finely enough is fed back along the screen to the cutting shafts via the upper shafts.

The infeed of this machine due to its large width over 4 shafts does not require additional depressing even with the bulkiest objects

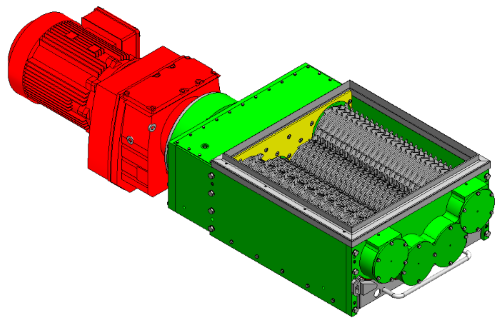

Each shaft has its own mechanically independent drive. This means that a wide range of movement and load concepts can be created in the machine control system to cope with even the most difficult cuttings.

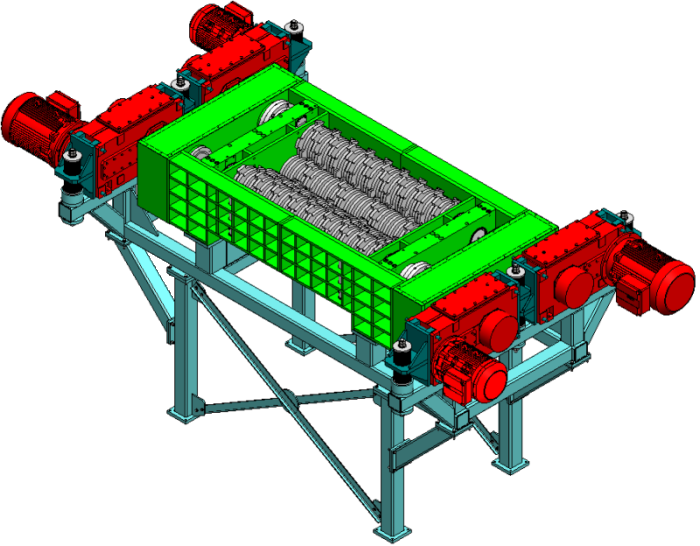

The cutterbar opening of the QUAD II x 1700 series is square, i.e. 1700 mm x 1700 mm. The QUAD 2300 model has an opening of length x width = 2300 mm x 1700 mm.

Special emphasis has been placed in the design of the QUAD II on the use of proven machine components and on simple maintenance procedures.

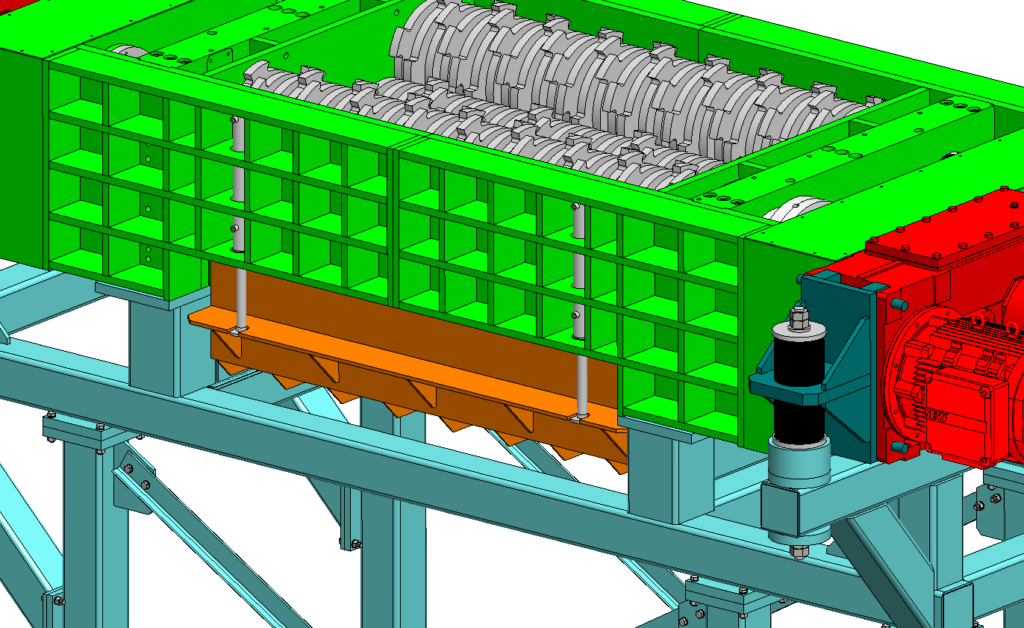

The drives are completely isolated from the cutting chamber, and any damage to the oil seals of the drives caused by cuttings residues is ruled out. For this purpose, a generous gap is taken into account so that dust and cuttings (as well as wire residues during tire shredding) can fall down after passing through the solid sealing of the cutting frame and are not pressed against the oil seals.

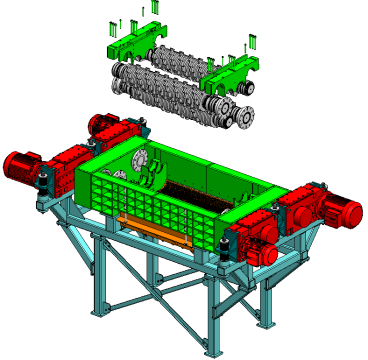

Despite the large weights, changing the cutting shafts is extremely simple: The solid frame bridges have a slightly conical fit in each other, and after the first loosening they are completely geometrically free. There is no risk of unwanted damage due to long-distance dry friction of steel on steel under load.

After loosening the proven Artech couplings, all 4 shafts can be removed upwards without any further assembly work on the drives.

All grease lubrications of the bearings are realized by the lower, standing frame parts, i.e. there is no need to mount on these parts either.

The cutting screen is mechanically locked and, if necessary, hydraulically pushed out of the machine frame or repositioned. It can be easily removed to the left or right side in existing stacker lugs.

Of course, the machine can also be operated without a sieve.

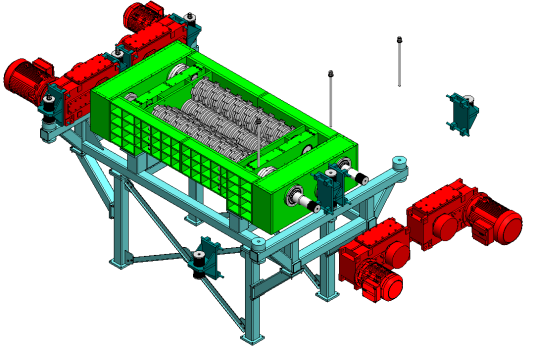

Convinced by the reliability of torsionally elastic drives, proven fixing elements from the Artech series have also been adopted here.

In order to meet the wide range of shredding applications, the drive of the machine can be dimensioned individually (usually in pairs) for each shaft in terms of power, torque, speed and safety factor of the gearbox.

The drive can be realized either hydraulically or electrically. The decisive factor for this design is the expected operating behavior with regard to speed and variance of the torque due to the material to be cut. The individual drives in the model series “Electric Drive” can be selected by the individual sizes of the series of Siemens/Flender gear units. With the sizes H3KH 10-15 a possible shaft torque of approx. 60,000 Nm – 150,000 Nm per shaft is available with an installed power of 75kW-130 kW per shaft.

The drives in the “hydraulic drive” model series are realized by Bosch Rexroth / Hägglunds brand high-torque motors, CA 140-240 series with maximum shaft torques of 120,000 Nm.

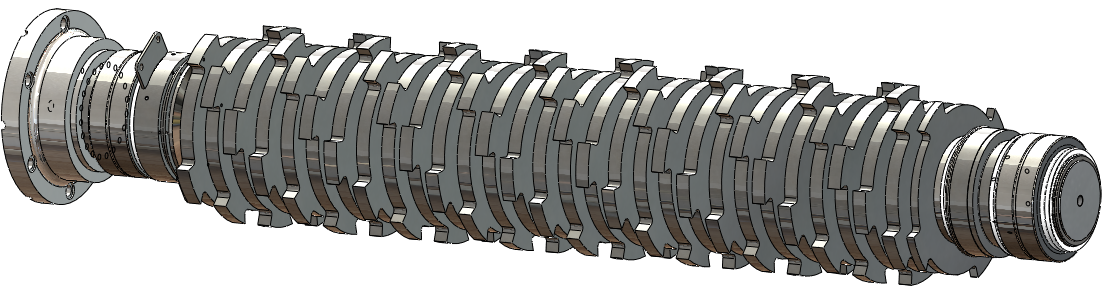

All cutting blades are made of high-strength, fine-grained material, they are characterized by a ductile, impact-resistant core.

These knives bend rather than break. The edges of the cutting blades are welded with highly doped tool steel. This edge armoring can be repeated an unlimited number of times. The choice of welding alloy depends on the expected cut material. Knife widths from 40 mm are available.

The ready-assembled slitter shafts are axially preloaded, and the slitters are hydraulically mounted with several hundred tons in favor of significantly increased strength against deflection of the shafts. The section modulus against deflection is almost tripled compared to an unstressed shaft.

The bearing arrangement on the shafts is excluded from the axial tension of the cutter mechanism.

The powerhouse in document destruction!

Security and data protection are the very top priorities when it comes to document destruction. Sensitive company data and personal data must be handled professionally by companies in accordance with the German Data Protection Act. Art. 28 EU-DSGVO be disposed of.

With the Quad 990, you are able to store files with protection class 3 up to security level P-4 according to the German Security Code. Federal Data ProtectionAct (BDSG) DIN 66399 to be destroyed.

Driving power: 55 kW

Cutting unit opening: 990 x 1000 mm

Number of slitter shafts: 4

Main shaft speed: 1/min 5 – 35

Direct drive: yes

Hydraulic trib: no

Weight: 4400 kg

Dengelhammer 2

24537 Neumünster

eMail: contact@vondermehden.com

Phone: +49 0432 1853 66 30