As a special service in the field of rotary shears, we offer the refurbished of used cutting blades.

Careful pre-heating and post-heating procedures as well as an automated welding process ensure a uniform and harmonized refinement of your blades. By always repeatable armor welds on the cut edges and in the area of the feed hook we can:

Thanks to a specially developed process, we are able to recondition (refine) wear parts in such a way that the service life of the highly stressed parts is significantly increased. Using automatic processes, a uniform and harmonious finishing of the parts is ensured. The finishing on the cutting edges and feed hooks can be repeated without any problems. The material used in each case for preparation is specially adapted to the use of the rotary shears in order to optimize the geometry of the blade and thus the cutting result.

The result of these measures is a significant reduction in your maintenance costs and an increase in your productivity.

Experience shows that the up-armor price is about 60% cheaper than the new part.

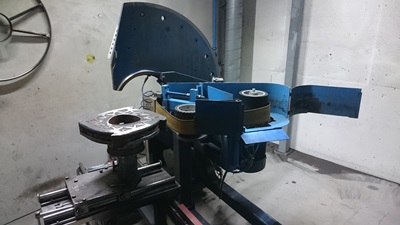

The knives and bushings to be reconditioned are first chamfered in the dry grinding shop. During chamfering, the outer contours (the cutting edge and the feed hooks) of the knives are ground at a 45° angle to create a better foundation for subsequent finishing. How much is ground off depends on the respective type of preparation and wear of the individual knife or bushing.

After the grinding process, cutting edges and feed hooks of the chamfered parts are finished in the welding shop. In this process, welding robots are used to precisely apply the various seams in a specific sequence one after the other to the part to be processed.

Due to the buildup welding process, the knives and bushings have a certain oversize, which is removed by contour grinding after cooling. Here, the knives then regain their exact shape. Finally, the workpieces are subjected to fine grinding in a wet grinding process. In this grinding process, the workpieces that still had an oversize are ground down to the target dimension to achieve the desired final dimension.

In addition to blade armor, we are also engaged in the production of new blades (as reserve sets or to complete blade sets). We manufacture complete blade sets, as well as individual blades, for all types of rotor-blade shears.

Detailed consultation is decisively important here and is aimed at reducing your maintenance costs. In detail, this relates to:

Use is made of certified quality steel only. Furthermore, all steps of production in our own manufacturing plant are personally .

The right sieve size can make a big difference in the performance of a machine. Therefore, very short-term changes are required. We can produce most standard-sized sieves in a very short time. Even Special sieves, such as of wear-resistant steel, can be produced.

Sieves should be replaced regularly, so that the maximum throughput can be achieved. We manufacture the sieves according to your wishes in order to achieve the desired particle size.

All necessary spare parts are manufactured in our own production. These include:

Upon request, the individual elements are assembled as ready-to-install shaft cutting units. If required, completely fitted cutting frames are prepared – a contribution to your operating safety.

An additional service is the repair of gears. In close cooperation with the gear manufacturers we can carry out such repairs at short notice.

Any changes you want, or proposals you have to make, will be taken up and implemented quickly. Adapt the technical strengths of other models to your own machinery and profit in this way from our knowledge of the market.

To enhance your operating safety we can prepare

for you, and even store them free of charge.

All of the components manufactured by us are assembled by our experienced fitters on site, or else in our own works. And when you need us, you’ll always find us ready to assist you at short notice, whether in Germany or elsewhere in Europe.

The provision of essential special tools and the punctual delivery of cutting units help ensure that your down times are reduced to an absolute minimum.

Dengelhammer 2

24537 Neumünster

eMail: contact@vondermehden.com

Phone: +49 0432 1853 66 30